SLS 3D Printer

The design and fabrication of a selective laser sintering (SLS) 3D printer.

This was a collaborative project with 4 other classmates over the span of 2 semesters. My roles were in materials and fabrication. Our work was published in ASME’s IMECE 2017.

Materialsy Things

A set of sieves was used to determine the particle size of some second hand nylon.

I performed a spectroscopy test on a sample of our material. This helped determine the wavelength of the laser spec’d for the machine.

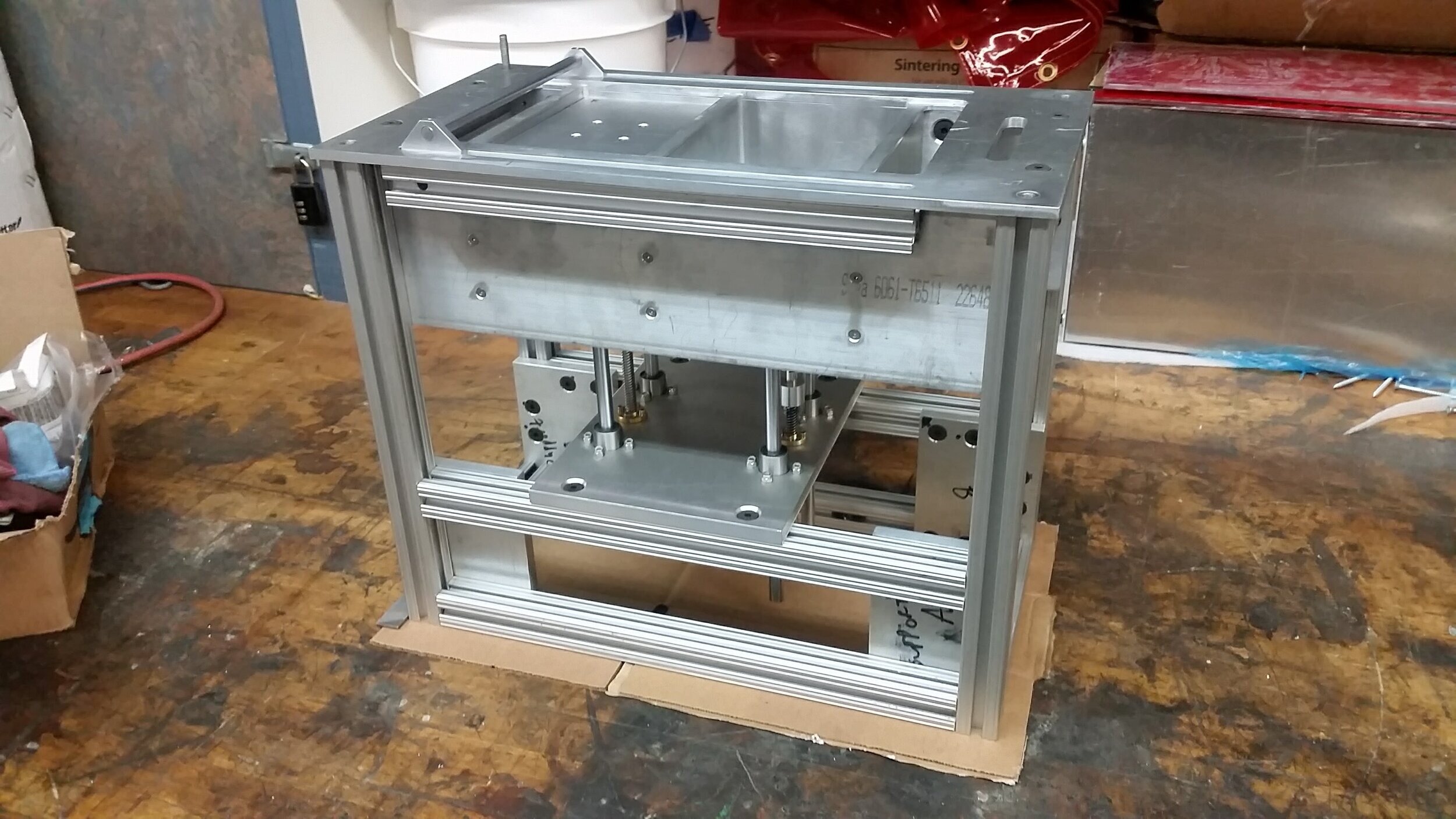

Fabricationy Things

New (to me) methods were used to make some of the parts with the equipment available. It was nice having multiple Kurt vices to work with! Can’t say when that will happen again.

Some different and seemingly more silly ways to reduce vibrations on wonky parts.

Organization of parts being completed during fabrication process.

We were somewhat resourceful when it came to material. A good chunk of these were fairly small parts which were easily recovered from the scrap bin in the shop. After parts were made, they were loosely assembled in stages and checked for fit.

Unfortunately, we were unable to wrap this one up in the time we planned for. The project and documentation was handed down to the next group daring to complete it.