Avid CNC aka CNC Router Parts

This setup was pretty simple. Just a simple piece together kit with a simple price, simple components and simple. The company Avid CNC/CNC Router Parts were easy to work with, answering all of my questions about their equipment promptly.

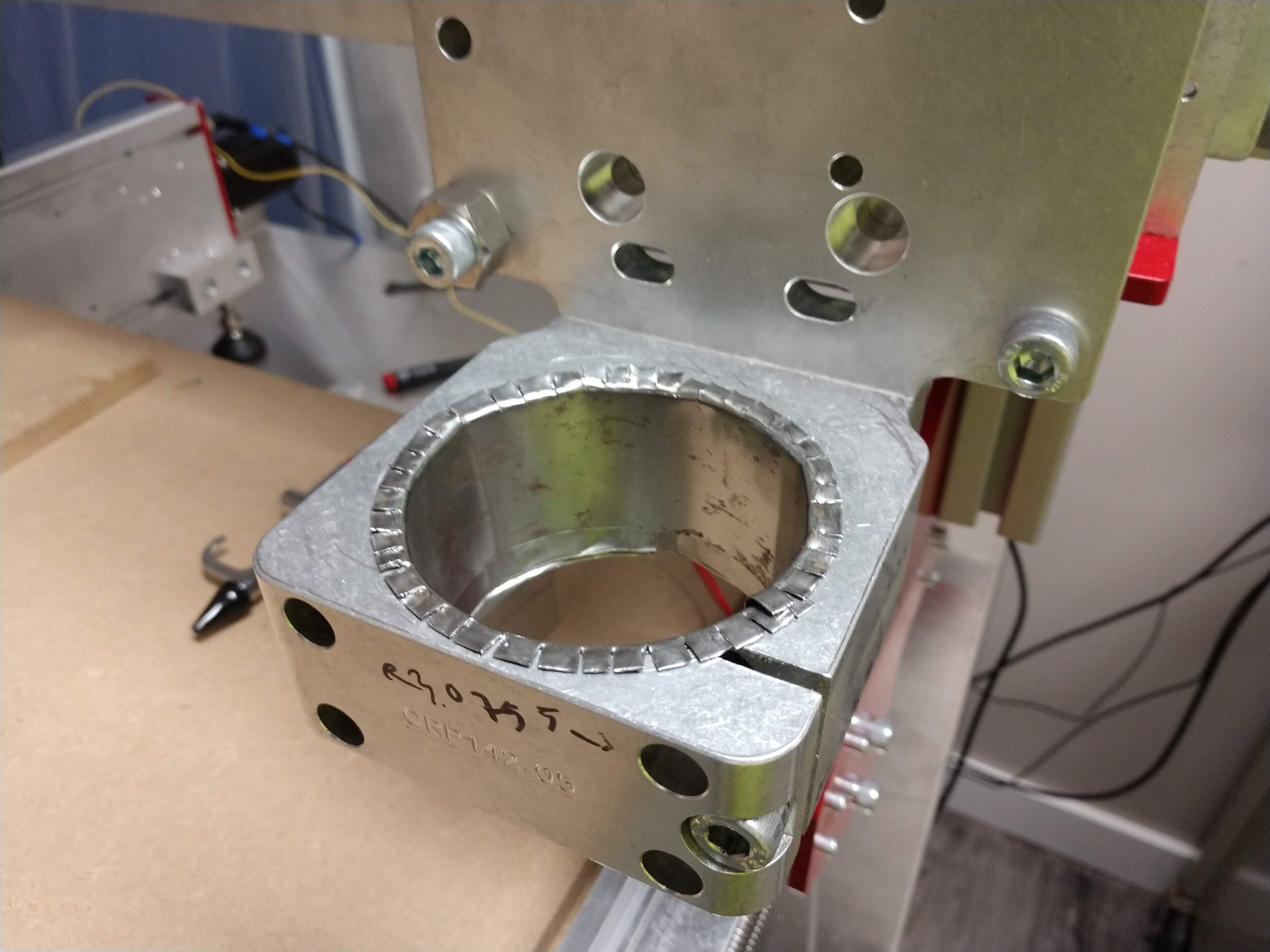

Our goal for this piece of equipment was pretty straight-forward at PPO (some would even say it was simple), we needed something to make positive molds of human heads for making masks through thermoforming. I spec’d out a 24”x24” Benchtop machine, as it had the greatest Z-travel I could find for the price. This type of Z-travel is necessary because of the long bits (6”) needed for the geometry of the human head. With an adjustable bed base and clarifying with one of the folks at Avid CNC, they claim a whopping 10.9” of travel (even though their site only states 9.3”). Those extras included auto-z leveling setup, proximity sensors, NEMA 23 controller with an ethernet smoothstepper, and Mach 3 for under $5k delivered. Not bad. Being that we were only doing light/easy to machine materials, this didn’t need much more thought. Last added bonus is that there is even talk of them coming out with an automatic tool changing setup.

Some other systems I considered I’ll list here with some pros and cons:

Stepcraft D-series: These didn’t have the Z travel we were looking for unfortunately, but they seem to be great machines out-of-the-box and worth their own description. They have professional looking enclosures, and if you opt for the HF-500 3-phase spindle you have access to the most inexpensive option for automatic tool changing out there. When I talked to these folks and asked about modifying their machine for whatever purposes, they said it would void any warranty, but they pointed me in the direction of an unaffiliated facebook group that they also keep in touch with.

Pocketnc: This one is just cool. If this came in the right envelope, I’m sure we would have ponied up for this 5-axis machine.

There were a number of other machines that didn’t have the envelope I was looking for in one axis or another. These machines typically had a standard endmill setup (e.g. castings and whatnot) that looked great for heavier duty applications: Sherline 58xx (13.6” x 11” x 5.4”), PM-25MV (19” x 7” x 13”), and of course the little bit pricier Tormach 440 (10” x 6.25” x 10”).

Pancake CNC: This one was the runner up, but we ultimately made the decision that we would have eaten everything we produced and no progress would have been made.

Gettin’ ready.

Almost there.

Aaaaaand rough framework pieced together. Just need wiring routed at this point.

Settling in to it’s new position next to the ping pong table

We even have neat little a room for it.

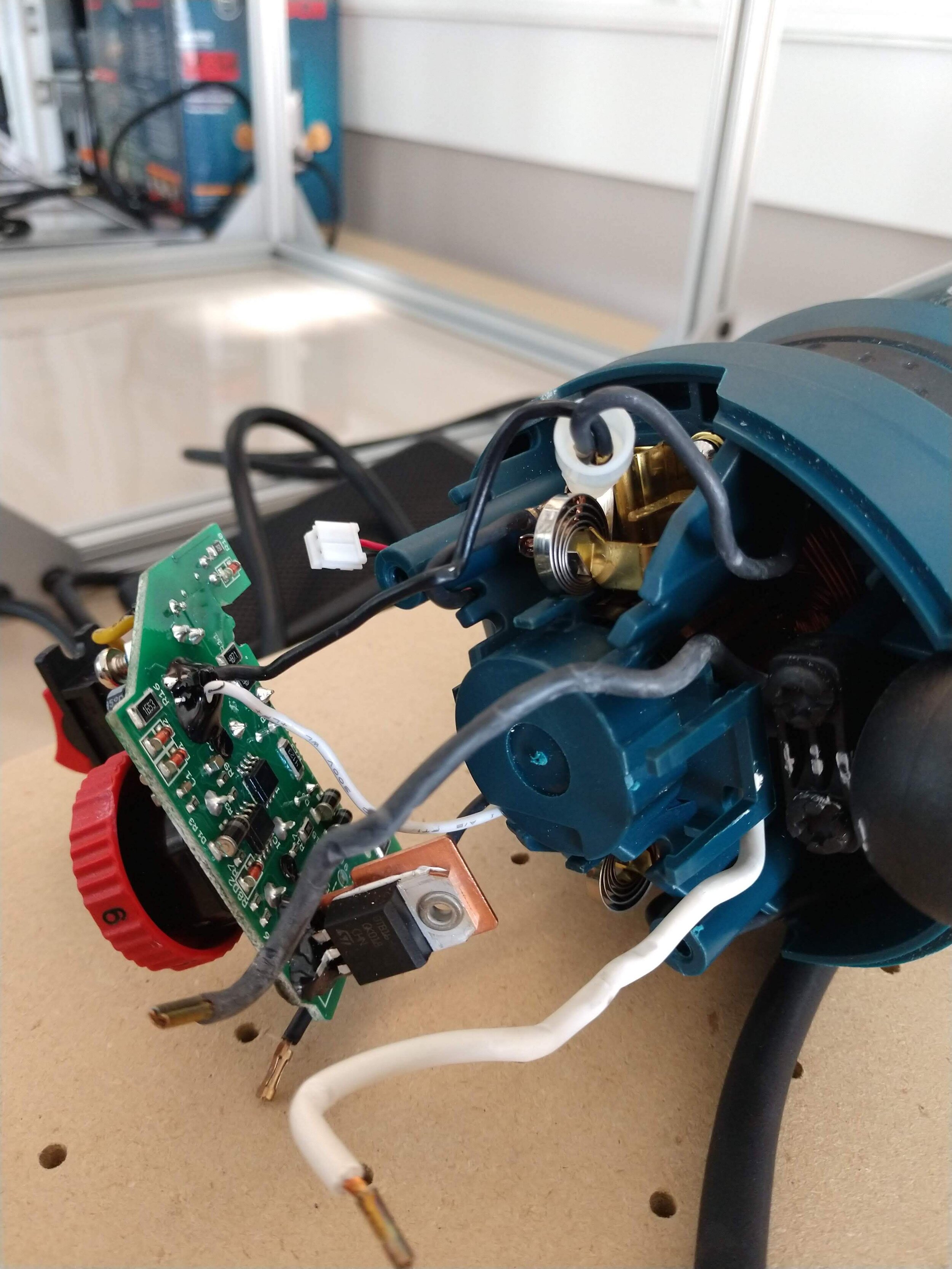

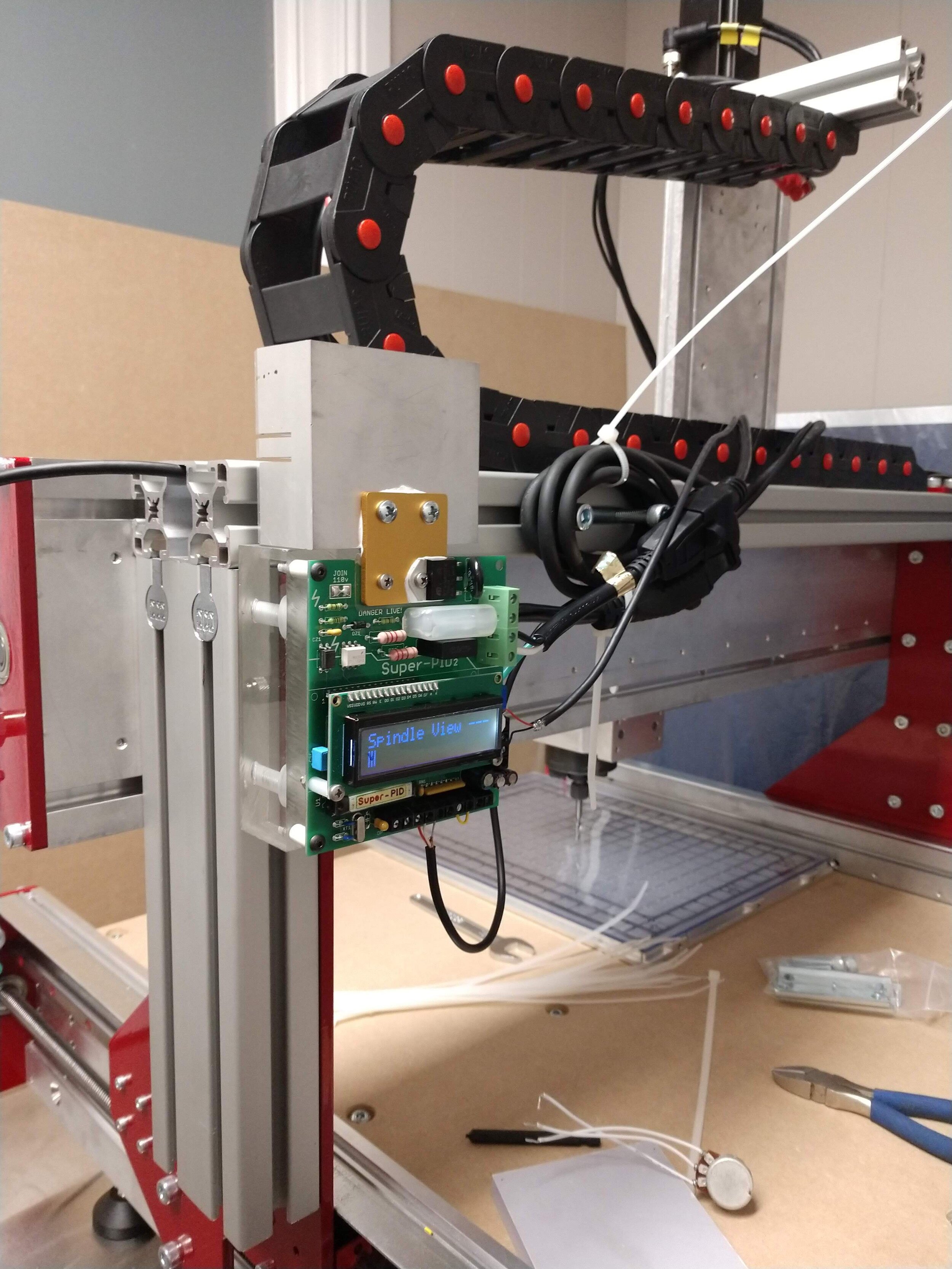

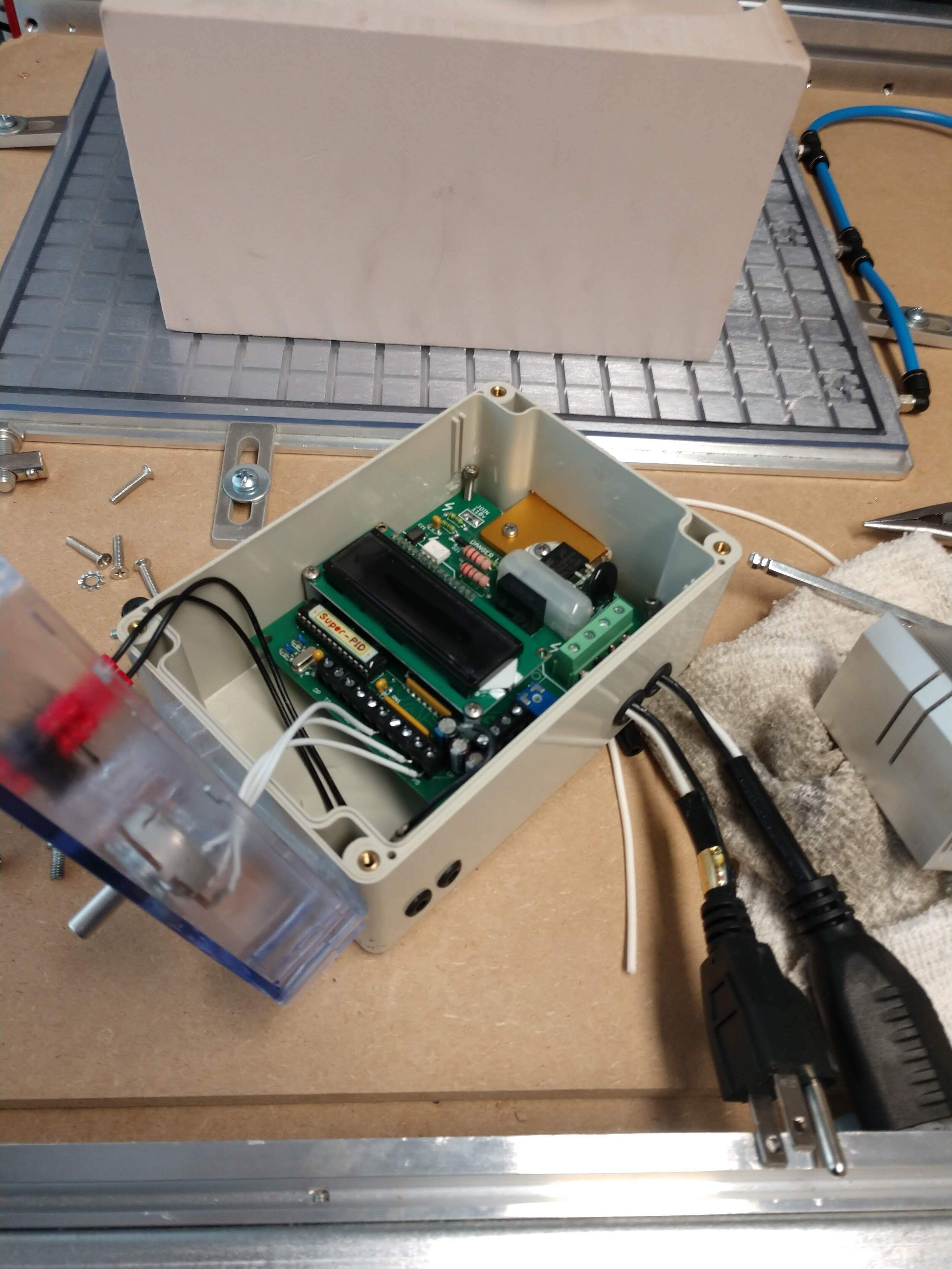

As far as router choice, I flipped a coin and got a Bosch Colt 1.25 palm router over the Dewalt 611…for no particular reason to justify one over the other. Unfortunately….it was the wrong choice. Nothing seemed out of the ordinary until I looked more into running that 6” bit. The biggest concern you’re gonna have is TIR (Total Indicated Runout). Routers weren’t designed with this kind of tooling in mind, and it could be argued that they don’t need to be. It makes sense that some may perform better than others, so when I was looking for kits to reduce runout with this kind of setup I ran across this page by Think & Tinker (beeteedubs, for those looking into these setups, it’s a great resource and I’ve already linked it 3 times if you’re counting), so first round was practice, second was perfection. There’s a couple of different slideshows below.